Remobile is a mobile phone inspection platform that produces consistent grading, evidence capture, and auditable inspection records.

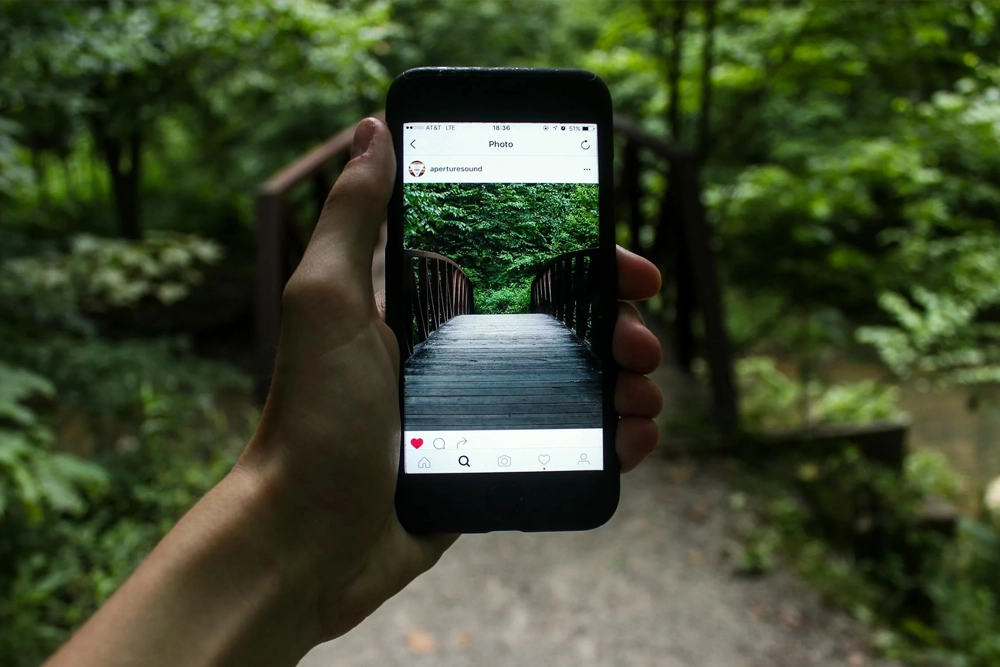

Functional Testing

Standard checks for touch, display, cameras, audio, mic, sensors, connectivity, charging, and more.

Read moreCosmetic Grading

Consistent grading with defect tagging and photo evidence for screens, frames, backs, and lenses.

Read moreEvidence & Audit Trail

Every inspection is traceable: who inspected, when, what changed, and the supporting evidence.

Read moreWhy Remobile

Consistent Grading

Reduce disputes and returns with standardised grading rules and clear defect tagging.

Evidence-First Reports

Photo-backed inspection reports that help QA, sales, and customers trust the outcome.

Faster Operations

Structured workflows and checklists help teams inspect faster without sacrificing quality.

Audit Trail

Track who inspected, when it happened, and what changed—built for accountability.

Export & Integrations

Use inspection data where you need it—reports for partners, feeds for listings, and internal dashboards.

RWA-Ready (Future)

Future roadmap: anchor certificate proofs on-chain to make verification portable and tamper-evident.

How Inspection Works

Create device record

Run functional tests

Capture cosmetic evidence

Assign grade & defects

Export report / verify

Designed for inspection teams, QA, and partners

Remobile focuses on real inspection workflows: repeatable steps, clear evidence, and a reliable audit trail. It helps teams reduce arguments about condition and make faster, cleaner decisions across refurb, resale, and returns.

Request a DemoWhat we check in a typical phone inspection

Minutes per device (typical)

Display & Touch

Touch accuracy, dead pixels, brightness uniformity, glass condition, burn-in checks.

Minutes per device (typical)

Battery & Charging

Charging stability, port health, cable fit, thermal checks, and battery indicators where supported.

Minutes per device (typical)

Cameras & Audio

Front/back cameras, focus, lens defects, speakers, microphone, and call audio checks.

Minutes per device (typical)

Cosmetics & Evidence

Standard angles, defect close-ups, and notes for scratches, dents, chips, and housing wear.

Minutes per device (typical)

Buttons & Sensors

Power/volume, mute switch (if any), proximity, gyro, compass, and vibration checks.

Minutes per device (typical)

Connectivity

Wi-Fi, Bluetooth, GPS, cellular signal (where possible), and SIM detection checks.

Minutes per device (typical)

Identity & Compliance

Device identifiers and status checks as required by your operational policy (configurable).

Minutes per device (typical)

Report & Export

Generate shareable reports and exports for internal systems, listings, and partner verification.

Frequently asked questions

A device record with test outcomes, defect tags, photos, inspector metadata, and an exportable inspection report.

Yes. You can configure defect categories and grading rules to match your operational standards.

Yes. You can share a report ID so partners can verify the inspection record and evidence (access rules configurable).

Not yet. The current product focuses on inspection and verification. The future roadmap includes optional on-chain anchoring of certificate proofs (RWA-ready).

Refurbishers, wholesalers, marketplaces, and any team that needs consistent device inspection with evidence-backed reporting.

Insights & updates

20

Jun

How to reduce disputes with evidence-first inspection reports

Learn how consistent grading rules and photo evidence improve trust across refurb, resale, and returns...

19

Jun

What “audit trail” means for refurbished phone operations

A practical explanation of traceability, accountability, and how to prevent internal QA disagreements...

18

Jun

Inspection checklist: what to standardise first

If you’re scaling volume, start by standardising these checks to keep speed and quality aligned...

17

Jun

From inspection records to RWA-ready provenance (future roadmap)

How to start with off-chain certainty and add on-chain proof later, without disrupting operations...